Importance of Thermal Inspections and Mapping

by siteadmin

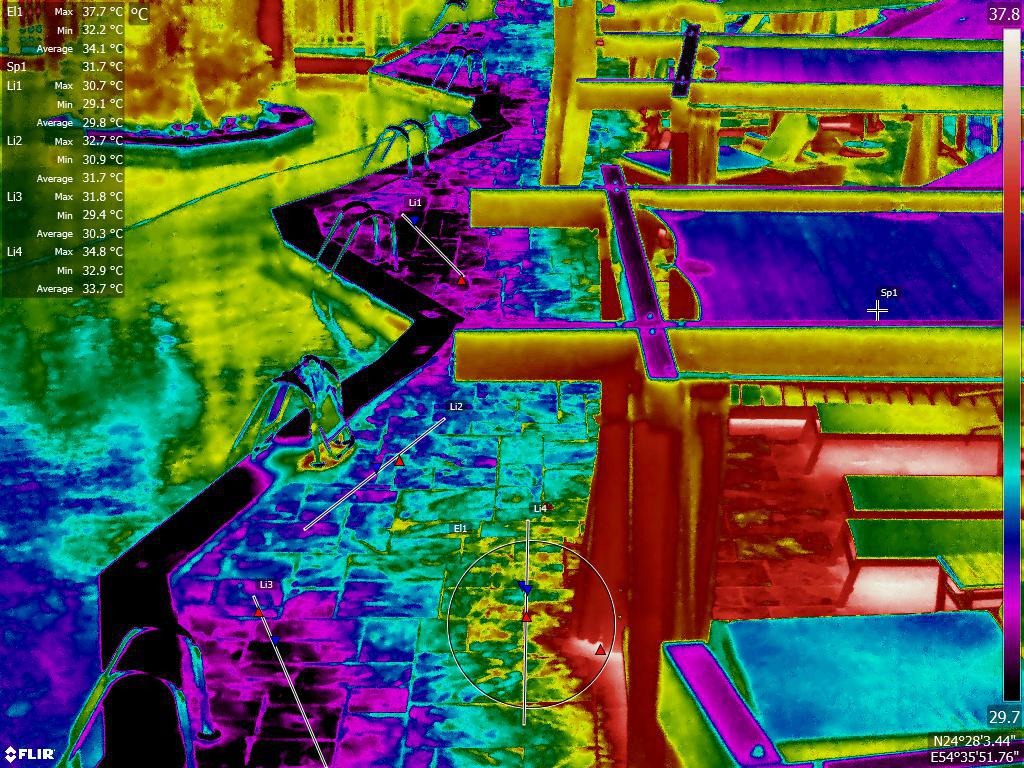

Thermal imaging, or infrared thermography, provides a snapshot of the surface temperature of an object or area. These images can detect a variety of problems including moisture in walls or roofs, leaks and air conditioning failures.

Using thermal drones for inspections can greatly reduce the cost of a manual inspection. The need for scaffolding to be constructed can also be eliminated which will save time and money.

Detecting Electrical Issues

When electrical current flows through a circuit, it generates heat due to resistance. That’s normal, but if excess heat is present, it could be a sign of an imbalance or an overloaded circuit. Thermal scans can identify these issues and help prevent power failures, fires, or electrocution.

Residential thermal imaging can detect problems that a typical home inspection would miss. These include leaking water, air leaks, faulty insulation, and moisture in the walls. The ability to identify these problems allows homeowners to take corrective action to reduce energy costs and improve the condition of their homes.

Using a thermal imaging camera also provides insight into the condition of heating, ventilation and air conditioning (HVAC) systems and insulation. In addition to identifying areas where more insulation is needed, thermal imaging can spot problems with air conditioning ducts and vents, furnaces, and air conditioners.

The ability to see through walls, wires and pipes makes thermal scanning an excellent tool for locating plumbing problems. Thermal images can help identify leaks in drains, hoses, and fixtures as well as problems with valves, fittings, and spigots.

A thermal image can also show the presence of mold and mildew. This is a common problem in older buildings and newer homes. Mold and mildew can lead to health and safety problems, so it’s important to address them as quickly as possible.

Thermal imaging is a powerful tool for assessing the quality of insulation and for detecting moisture damage in building components such as drywall, roofs, walls, and basements. The thermal images can also help determine the source of moisture, such as a wet or damaged stud or a rotted wall.

One of the most common industrial applications for thermal imaging is locating levels of liquids, gases, fluidized solids and sludge in tanks, vessels and silos. This is difficult to do with a visual inspection and requires specialized sensors. Thermal imaging allows a drone to easily find these locations and provide accurate measurements.

When conducting a thermal scan of an electrical power system, it’s important to do so while the equipment is under load. This is because excessive heat is often the first indicator of a problem and it’s best to catch these issues before they cause a breakdown or even a fire.

Identifying Leaks

Infrared scanning is a great way to spot leaks in buried pipelines, whether it's hot or cold water. Leaks are a major problem when it comes to buried piping systems, and they can lead to costly pipeline issues and repair costs if not detected quickly enough. Infrared mapping can help identify these types of leaks by detecting the point of highest temperature difference on an anomaly map, making them easier to find and fix.

Thermal mapping can also be used to spot areas that need additional insulation or complete replacement, reducing energy consumption. This can be a great tool for utility companies, which can then offer their customers the results of these scans along with access to a comprehensive financing program that allows them to make energy efficiency upgrades in phases as they pay off their regular utility bills.

This process can be particularly helpful in the pharmaceutical industry, where thermal mapping plays a vital role in validating temperature uniformity across critical areas and equipment. It can also be used to identify and resolve any problems that would impact product quality, helping ensure compliance with Good Manufacturing Practices (GMP) regulations.

While thermal imaging is an important part of any inspection, it should be used in conjunction with a visual inspection to locate electrical issues and plumbing leaks. In some cases, it may be necessary to dig up the affected area of a buried pipe to perform a more detailed examination and complete repairs. Using drone-based thermal imaging, however, allows our crews to quickly locate these leaks and avoid disrupting the production schedule.

When conducting a thermal scan, it is best to choose a time of day when any temperature differences or anomalies will be most pronounced. This is usually in the early morning or late afternoon, when the sun's rays are not directly overhead. Additionally, the survey should take place when wind is minimal, as it can cause air to move around and confuse the readings. Finally, a buried piping system survey should be conducted at night or during the winter, as the operation of IR cameras can be impacted by sunlight, known as solar loading.

Detecting Temperature Excursion

For pharma companies with temperature-sensitive products that require tighter control and storage conditions, it’s crucial to have the right temperature mapping process in place. Using mapping helps to ensure that product loss due to excursions is minimized, and that your company can continue to meet regulatory compliance requirements and earn accreditations while maintaining quality and efficiency.

Temperature mapping involves a detailed survey designed to accurately assess and document the environmental conditions in an active storage facility. This includes refrigerators, freezers (including ULTs), incubators and cold rooms. During the survey, each individual area is monitored with a thermal imaging camera and temperature data loggers. The temperature loggers are positioned so they are in proximity to the most likely areas where a temperature excursion might occur. The survey is conducted over a two-week period to accommodate procedures, such as loading, unloading and forklift movements, that can cause temperatures to deviate from the expected range. The resulting map and data help you identify hot and cold spots, which are the locations that need additional monitoring in your facility.

In addition to identifying the location of thermal excursions, mapping allows you to pinpoint the source. This information is critical in making decisions on whether to retain, repair or dispose of affected product, and in developing a new storage protocol going forward. It can also be helpful for future risk assessments or insurance claims.

The temperature mapping process is a highly detail-oriented, rigorous activity that should be a part of the qualification of any new temperature-controlled chamber or space in your facility. With the proper planning, the mapping project can be straightforward and efficient.

While a thermal image is helpful in identifying problems, it should always be used alongside other tools to confirm your findings. For example, a borescope or moisture meter can be useful in confirming what you see on the thermal image. Likewise, a multimeter or blueprint of the building can provide more context and help you interpret the temperature anomalies you see on the thermal image. Ultimately, using a combination of tools can be the most effective way to inspect an area and get the most out of your thermal imaging system.

Identifying Defects

Using thermal imaging to scan real estate facades for energy leaks is a highly efficient method that is particularly well suited for colder weather conditions. However, exterior scans require the use of a specialized mount, which is often difficult to operate in windy conditions. In these situations, thermal imaging can be used indoors to identify air leaking through windows and other penetrations in the building envelope, enabling energy assessors to focus their efforts on more problematic areas.

In addition, the use of drone-generated thermal maps allows for the inspection of more complex surfaces. Whether the building in question is an industrial or commercial structure, many components are subject to wear and tear, causing a number of issues that can be easily identified by thermal imaging. For example, thermal mapping can highlight cracks in concrete, which are often indicative of potential structural issues or damage.

For this reason, it’s important to choose the right sensor for your Thermal Inspections and Mapping needs. Fortunately, the latest camera technology makes it possible to achieve better resolution while flying at a safer distance. The new processing method combines contrast evaluation and defect boundary identification in order to provide more precise and reliable results. Moreover, the advanced processing mode enhances the visibility of defects in a variety of different situations, such as when they are elevated in depth or located at plate borders where temperature gradients might occur.

As a result, the advanced process provides a significant improvement in the detection capability of both the GFRP and PVC samples compared to traditional methods. A detailed comparison of the thermal acquired sequences illustrates that the advanced processing approach significantly improves the defect detection and shape indications for several analyzed defects. This demonstrates that the combination of accurate contrast evaluation and a dedicated image processing mode is critical to the simultaneous defect detection and mapping process, especially for the recognition of buried discontinuities.

Thermal imaging, or infrared thermography, provides a snapshot of the surface temperature of an object or area. These images can detect a variety of problems including moisture in walls or roofs, leaks and air conditioning failures. Using thermal drones for inspections can greatly reduce the cost of a manual inspection. The need for scaffolding to…

Recent Posts

- Experience Unmatched Quality and Reliability with Under One Roof’s Roofing Services

- Transform Your Home with Expert Cabinet Painting and Refinishing by California Cabinet Finishes and Refacing in Austin, TX

- Affordable Fencing Solutions: Fence Company Rochester NY Offers Insight on the Cheapest Fence Installations in Rochester, NY

- Expert Roofers Columbus Shares Insights on the Roofing Installation Process in Columbus, GA

- Exploring the Drawbacks of Duct Cleaning: Insights from Air Vent Cleaning Charlotte